Metal Solutions: The Solution for your Cutting Needs

- mmonarko

- May 10, 2022

- 2 min read

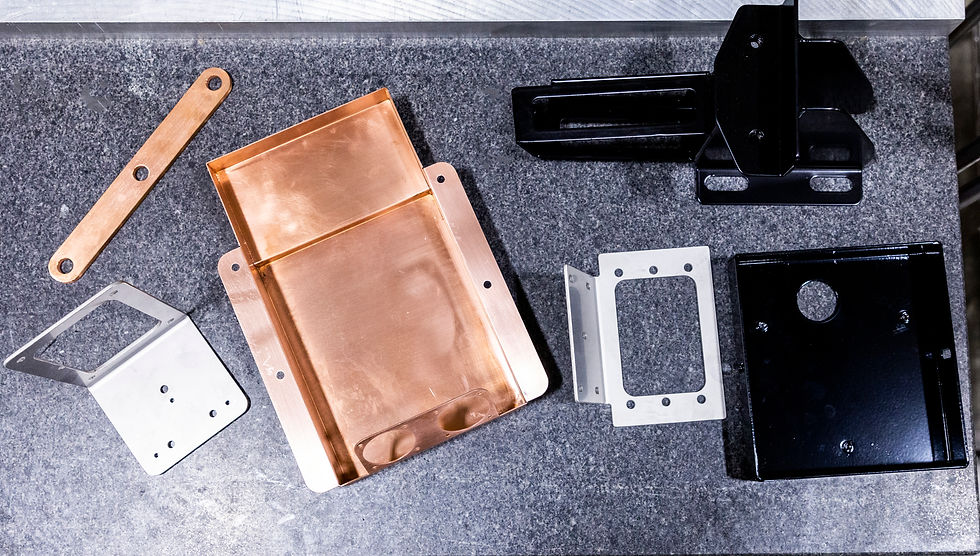

Metal Solutions Inc. is a one-stop shop for metal cutting services. We are equipped with a laser and 5-axis waterjet, along with the talented employees that operate these machines.

Laser cutting is a process that aims high-powered laser beams through optics to cut through material. It is typically the most accurate and fastest cutting method. There are various types of lasers such as carbon dioxide (CO2), fiber, and neodymium (Nd). A fiber laser is a type of laser which uses fiber doped with rare-earth elements as a medium, and these types of lasers are typically faster, more efficient, and less expensive to operate.

Metal Solutions is equipped with an AMADA ENSIS 3kW fiber laser. It can process sheet and plate that is 60” wide and 120” long. Thickness varies by material. We can cut steel up to 1” thick, aluminum up to ½” thick, stainless up to 5/8” thick and copper up to ¼” thick. Our laser utilizes a highly innovative resonator to adjust the diameter of the laser beam automatically and precisely. This unique feature enables continuous processing of thin-to-thick materials with no lens change or additional setup required, resulting in ultimate efficiency.

If your cutting requirements are thicker than what our laser can accommodate, we can cut virtually any material up to 4” thick with our waterjet. Waterjet cutting uses a stream of high-pressured water mixed with abrasives to cut steel, stainless, copper, aluminum, brass, plastics, and foam.

One of the biggest advantages of waterjet cutting is its inherent cold cutting quality. Materials cut using this process undergo no thermal stress, meaning no hardening or additional warping of the material being cut. This is especially beneficial for aerospace applications.

Metal Solutions is equipped with a Techjet-X3® 4100G Waterjet capable of cutting up to 4″ thick by 72” wide and 144” long. The machine is equipped with a PAC 60™ - Precision Angle Control 5-axis Cutting Head, allowing for 60 Degree Beveling Capability. This produces parts with a true angle up to +/- 60° with continuous rotation.

Please visit our website www.metalsolutionsinc.net to learn more about our cutting and manufacturing capabilities, or send an inquiry to info@metalsolutionsinc.net. We look forward to working with you on your next project!

Comments